Construction and Demolition Waste Sorting: Transforming Waste into Resources

Construction and demolition (C&D) waste accounts for more than one-third of all waste generated within the European Union, representing a significant opportunity for resource recovery. This waste stream includes diverse materials like concrete, bricks, metals, wood, glass, and plastics, originating from construction projects, demolitions, and infrastructure maintenance.

The Value of Sorting C&D Waste

C&D waste contains valuable materials that can be recycled into new products or used as secondary raw materials. Efficient sorting lines are critical to maximizing material recovery, minimizing environmental impact, and reducing landfill reliance. Advanced technologies in C&D waste sorting enable businesses to achieve high levels of purity and productivity, unlocking the economic and environmental potential of this waste stream.

Challenges and Solutions in C&D Waste Sorting

- Material Composition and Variation:

C&D waste often includes a wide range of materials in varying sizes and conditions. Advanced sorting lines address this complexity by using a combination of mechanical, magnetic, and optical technologies. - Regulatory Pressures:

EU regulations demand higher recycling rates and reduced landfill use. Investing in state-of-the-art sorting solutions ensures compliance and positions businesses as leaders in sustainable waste management. - Operational Efficiency:

High throughput and precise sorting are essential to handling large volumes of waste efficiently. Modular and scalable systems ensure adaptability to evolving demands.

System Boundaries in C&D Waste Management

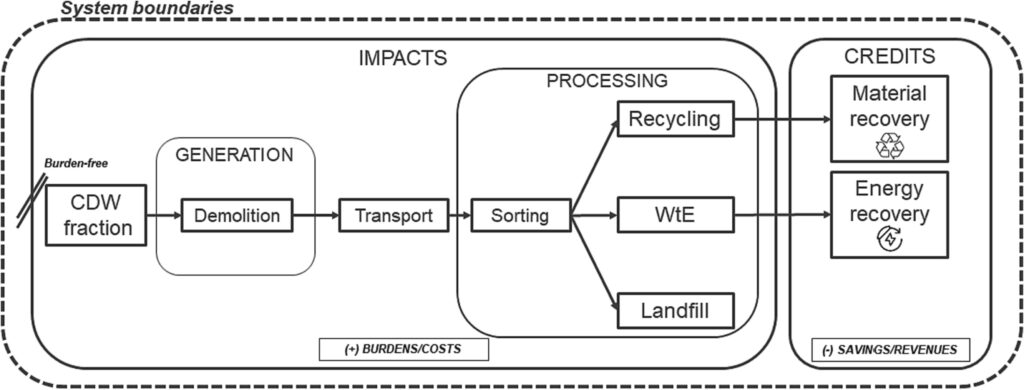

The lifecycle of construction and demolition waste involves multiple stages—generation, transportation, processing, and material recovery. Each stage impacts environmental and financial outcomes.

Key stages and impacts:

This framework underscores the importance of investing in advanced sorting technologies to reduce burdens while maximizing credits through efficient material and energy recovery.

System boundaries for the three classes of waste management treatments. Impacts (left side) include burdens (LCA) and costs (LCC) coming from the waste management of each fraction whereas credits (right side) include savings (LCA) and revenues (LCC) coming from the material and energy recovery (Caro et al., 2024).

C&D Waste in the EU: Challenges to Achieving the 2035 Goal

The European Union has set ambitious targets to reduce landfill use to less than 10% of all waste by 2035 while increasing material recovery and recycling rates. C&D waste plays a critical role in these efforts, but several challenges must be addressed:

- Fragmented Recycling Infrastructure

While some EU nations have advanced recycling systems for C&D waste, others lack sufficient infrastructure, leading to disparities in material recovery rates. To meet the 2035 target, the EU needs a unified approach that supports infrastructure development in underperforming regions. - Inconsistent Waste Management Practices

Variations in national regulations and sorting standards create inefficiencies and hinder cross-border collaboration. Establishing harmonized practices and standards for C&D waste sorting is essential for improving recycling outcomes across the EU. - Waste Composition and Contamination

Mixed and contaminated C&D waste poses significant challenges to effective sorting and recycling. Investments in advanced technologies such as AI-driven optical sorters and robotic systems can help overcome these barriers by improving material purity and recovery rates.

Solutions for Tackling C&D Waste Challenges in the EU

- Developing High-Tech Sorting Facilities

Building state-of-the-art sorting facilities equipped with advanced separation technologies is crucial. These facilities can process large volumes of waste efficiently, ensuring higher material recovery and reducing landfill dependency. - Promoting Circular Economy Initiatives

Encouraging the reuse of materials such as bricks, wood, and metals through circular economy programs can significantly reduce waste generation. EU funding programs can support businesses in adopting these practices. - Enhancing Policy Frameworks

Strengthening regulations to mandate higher recycling rates and provide incentives for recycling C&D waste can drive compliance. Policies that support the integration of secondary raw materials into construction projects will further promote sustainable practices. - Fostering Innovation and Collaboration

Partnerships between governments, waste management companies, and technology providers can accelerate the development of innovative solutions. Sharing best practices and technological advancements across member states will improve overall recycling efficiency.

Key Features of Azortum's C&D Waste Sorting Solutions

Efficient Construction and Demolition Waste Sorting Line

- Capacity: 25 t/h of mixed construction and demolition waste

- Output Fractions:

- 0-20mm fine material

- 20-80mm light material (plastic, paper, etc.)

- 20-80mm heavy material (stones, wood pieces)

- 80-150mm light material

- 80-150mm heavy material

- Oversized material, sorted into wood, stone, steel, and plastic fractions

Operation Workflow:

- Pre-Sorting: Oversized and heavy materials are removed manually.

- Screening: Material is separated into multiple fractions via a two-tier screen.

- Magnetic Separation: Magnets extract ferrous metals from the waste stream.

- Air Separation: Lightweight materials are separated from heavier fractions for purity.

- Fine Material Handling: Sand and dust are directed to a separate pile.

Advanced C&D Waste Sorting Technologies

Eddy-Current Separators

Eddy-current technology enables efficient separation of non-magnetic metals such as aluminum and copper. These systems recover valuable resources, improving economic returns and reducing waste sent to landfills.

Optical Sorting Systems

By leveraging sensors and AI, optical sorters identify and separate materials like plastics and wood based on their color, shape, and composition. This ensures high precision and minimizes manual labor requirements.

Robotic Arms

Robotic sorting systems provide consistent and rapid sorting, increasing operational efficiency and maintaining high-quality output.

Modular Designs

Azortum’s modular systems allow for easy upgrades and expansions, adapting to changes in waste composition, regulatory requirements, or processing capacities.

Benefits of C&D Waste Sorting with Azortum

Why Choose Azortum for C&D Waste Sorting?

- Experience and Expertise: With years of experience in waste management, Azortum delivers innovative, reliable solutions for complex sorting challenges.

- Comprehensive Support: From consultation to installation and ongoing maintenance, Azortum provides end-to-end support.

- Technological Leadership: Our systems incorporate the latest advancements in sorting technologies, ensuring efficiency and precision.

Partner With Azortum for C&D Waste Management

Transform your construction and demolition waste into valuable resources with Azortum’s advanced sorting solutions. Whether you’re looking to enhance operational efficiency, comply with environmental regulations, or reduce costs, our customized systems are designed to deliver exceptional results.

Contact us today to learn more about how Azortum can revolutionize your C&D waste sorting operations.

Cited Sources:

- Environmental and socio-economic effects of construction and demolition waste recycling in the European Union (2024)

The current state of Construction and Demolition Waste Sorting in the EU.

Expert Design & Installation for Your Waste Sorting System!

At Azortum, we specialize in crafting tailored solutions designed for sustainable operation and maximum profitability for your business. Contact us today to share the details of your next project—we’re eager to collaborate!

We have received your information and will be in touch with you shortly. Thanks!